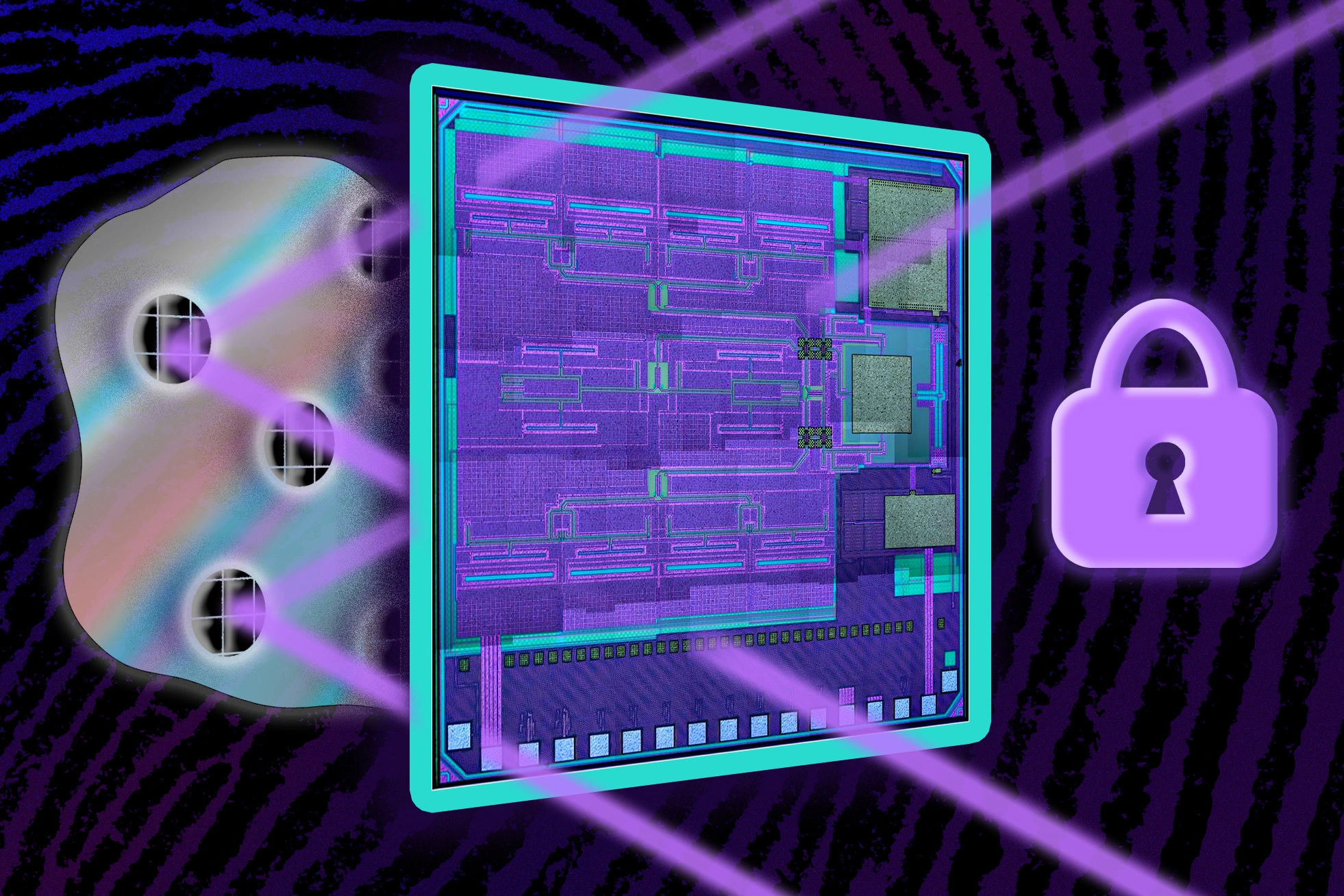

TL;DR MIT researchers have developed an antitampering ID tag that is tiny, cheap, and secure. It is several times smaller and significantly cheaper than the traditional radio frequency tags that are used to verify product authenticity. The tags use glue containing microscopic metal particles. This glue forms unique patterns that can be detected using terahertz waves. The system uses AI to compare glue patterns and calculate their similarity. The tags could be used to authenticate items too small for traditional RFIDs.

If there were collisions in the output you’d see them while scanning those thousands of entries. And if they release a new model you can use it going forward and keep scanning the old items with the old one.

This happens in inventory sometimes, new technology comes out, you have to update asset tags.

Tell me you’ve never developed commercial security software without telling me. “If it works a few thousand times without collisions it should be reliable enough”. That’s not even good enough for tamper proof seals on medication and yogurt jars let alone applications that require the sender and recipient to use a dedicated tetrahertz scanner to validate.

Nobody said anything about security applications, lol. It’s a proof of concept and you’re getting all worked up over complete hypotheticals. Where did you even get the idea that it would have collisions within thousands?

In security applications you need to account for actors with a marked interest in causing a collision but in an inventory scenario you simply generate IDs randomly until you get one that’s not a duplicate. There’s no problem using a hash algorithm with collisions if the probability is small enough. There are tons of scientific labs using MD5, btw.